Comprehensive Guide to Cement Silos in Modern Business Operations

Cement silos are vital components in the construction, manufacturing, and material handling industries. They serve as efficient storage solutions for bulk cement, facilitating seamless supply chains, reducing logistical costs, and improving overall productivity. As the backbone of many large-scale projects, cement silos exemplify the intersection of engineering ingenuity and operational efficiency.

Understanding the Role and Importance of Cement Silos in Business

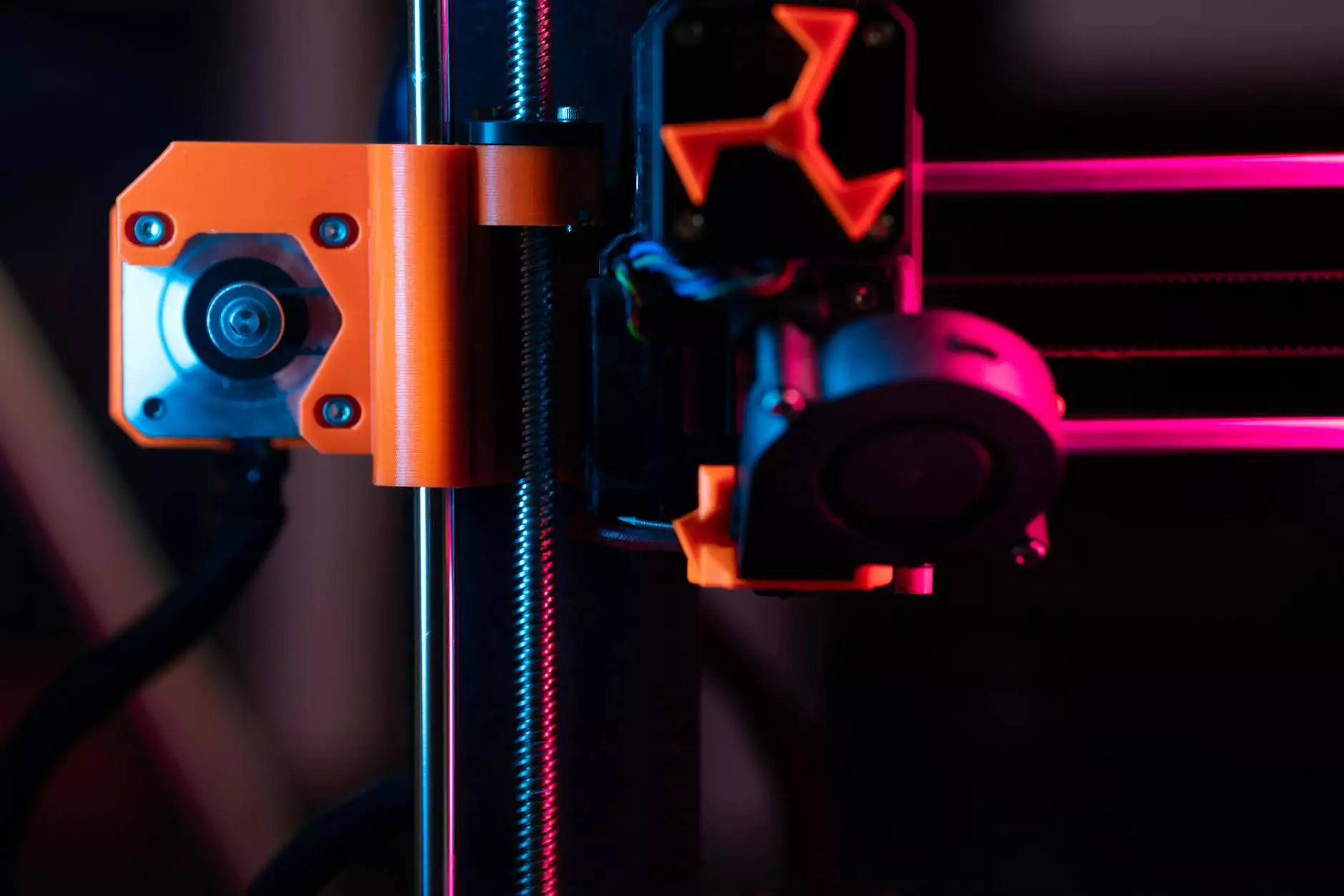

In today's fast-paced business environment, especially within the construction and electronics sectors (like 3D printing), the demand for reliable material storage systems is more critical than ever. Cement silos are not merely containers but are sophisticated structures designed to optimize the storage, handling, and dispensing of cement in various industrial processes.

Historical Development and Evolution of Cement Silos

The concept of bulk material storage has evolved significantly over the past century. Initially, simple open-air storage pits and basic containers were used, but these methods presented issues such as material degradation, contamination, and environmental exposure.

The advent of steel and reinforced concrete led to the development of durable, weather-resistant cement silos. Modern designs incorporate advanced features like aeration systems, automation, and corrosion protection. These innovations have allowed businesses to scale up operations while maintaining high standards of material quality and safety.

Advantages of Using Cement Silos in Business Operations

- Enhanced Storage Capacity: Cement silos can store large quantities of bulk cement, ensuring continuous supply and minimizing downtime.

- Cost Efficiency: Reducing theNeed for multiple delivery trips and lowering material waste lead to significant cost savings.

- Improved Quality Control: Protected storage minimizes environmental effects such as moisture and contamination that can degrade cement quality.

- Automation and Monitoring: Modern silos feature integrated sensors and automation systems for real-time inventory tracking and controlled dispensing.

- Space Optimization: Vertical design maximizes storage capacity within limited footprints, especially advantageous in urban construction sites.

- Environmental Safety: Closed systems prevent dust emissions and spillage, contributing to safer and cleaner work environments.

Design and Construction of Cement Silos: Key Considerations

The design of a cement silo must align with specific project requirements, environmental conditions, and operational loads. Key factors influencing design include capacity, materials, accessibility, and integration with other equipment.

Material Selection for Durability and Safety

Most cement silos are constructed from high-quality steel, often with protective coatings to resist corrosion. Reinforced concrete options are also available, especially for larger or permanent installations.

Structural Design Features

- Vertical Cylindrical Shape: Facilitates uniform flow of cement and maximizes capacity.

- Foundation and Support: Robust foundations ensure stability under heavy loads and seismic activity.

- Discharge and Feeding Systems: Includes rotary valves, screw conveyors, or pneumatic systems for controlled dispensing.

- Ventilation and Aeration: Prevent moisture buildup and clumping during storage.

- Access Points and Maintenance: Hatches, ladders, and cleaning ports allow for routine inspections and repairs.

Innovations in Cement Silo Technology by Polygonmach

Polygonmach leads the industry through innovative designs and comprehensive solutions for cement silos. Their engineering teams integrate cutting-edge technology to create silos that align with modern business needs, including electronics integration and compatibility with 3D printing manufacturing techniques.

Their advanced cement silo models feature automated control systems, real-time diagnostics, and modular structures for easy expansion. Polygonmach prioritizes sustainability, employing eco-friendly materials and energyefficient systems to minimize environmental impact.

Role of Cement Silos in Modern Construction and Manufacturing

In the construction industry, especially within large-scale infrastructure projects, cement silos are indispensable. They enable continuous, rapid concrete production essential for timely project completion. They also facilitate the use of electronic control systems, ensuring precise material measurement and reducing waste.

Within the realm of 3D Printing and electronics, cement and other composite materials are increasingly being used to create innovative components. Advanced silos are designed to accommodate specialized materials, supporting the transition towards more sustainable and lightweight construction materials.

Environmental and Safety Considerations in Cement Silo Deployment

Safety is paramount when operating heavy-duty storage solutions like cement silos. Proper installation, regular maintenance, and adherence to safety protocols prevent accidents and structural failures. Additionally, environmental concerns such as dust emissions and water runoff are addressed through enclosed systems, dust suppression techniques, and environmentally responsible disposal methods.

Operational Best Practices for Maximizing Silo Efficiency

Effective operation of a cement silo involves meticulous planning and routine maintenance. Some best practices include:

- Regular Inspection: Check structural integrity, seals, and safety devices.

- Moisture Management: Ensure proper aeration and humidity control to prevent cement clumping.

- Automation Utilization: Leverage embedded sensors for inventory management and process automation.

- Staff Training: Educate personnel on operational procedures and safety measures.

- Efficient Discharge Procedures: Use controlled systems to minimize material wastage and dust emissions.

Future Trends in Cement Silo Technology and Business Integration

The future of cement silos is closely tied to technological advancements and industry needs. Anticipated innovations include:

- IoT Integration: Internet of Things (IoT) devices for real-time monitoring, predictive maintenance, and remote operation.

- Smart Automation: Fully automated silos with AI-powered systems for optimal energy use and fault detection.

- Sustainable Materials: Use of recycled steel and environmentally friendly coatings.

- Modular and Mobile Silos: Easily transportable units for temporary projects or expanding business needs.

- Digital Twins: Virtual modeling of silos for design optimization, troubleshooting, and training.

Choosing the Right Cement Silo Partner: Why Polygonmach Stands Out

When selecting a provider for your cement silo needs, it's crucial to partner with industry leaders that combine experience, innovation, and customer-centric solutions. Polygonmach exemplifies these qualities, offering tailored solutions that advance your business effectively.

Their expertise in electronic systems integration, emergency safety features, and modular design ensures that companies are equipped with the best tools for sustainable growth and operational excellence.

Conclusion: Cement Silos as a Cornerstone of Modern Business Success

As industries continue evolving, the significance of advanced, reliable cement silos will only increase. They are essential for streamlining operations, enhancing product quality, and ensuring environmental compliance. Investing in state-of-the-art silo technology reflects a commitment to efficiency and sustainability, positioning your business ahead of competitors.

With the leadership and innovative offerings from Polygonmach, companies can unlock new levels of operational excellence, embracing future trends while maintaining safety and environmental standards. The integration of electronics and smart technology within cement silo design fuels innovation across construction, electronics, and 3D printing sectors.

Final Thoughts

Embrace the future of bulk material storage by choosing cutting-edge cement silo solutions—because your business's success depends on the foundation you build on. Whether for large-scale construction, electronic manufacturing, or the cutting edge of 3D printing, the right silo system is your strategic advantage.