Harnessing FDM 3D Printing for Innovative Business Solutions

In the rapidly evolving world of technology, the adoption of Fused Deposition Modeling (FDM) 3D printing has changed the landscape of product design and manufacturing, propelling businesses toward greater innovation and efficiency. This article delves into how organizations can leverage FDM 3D technology to refine their processes, reduce costs, and unlock unique opportunities for product development.

Understanding FDM 3D Printing Technology

FDM 3D printing, also known as Fused Filament Fabrication (FFF), is a widely used additive manufacturing process that builds objects layer by layer from thermoplastic materials. This technology operates by melting a thermoplastic filament, which is then extruded through a heated nozzle to create three-dimensional objects. Let’s explore the fundamentals and benefits of FDM in more detail.

The Principles of FDM 3D Printing

- Material Selection: FDM utilizes a variety of thermoplastic materials such as PLA, ABS, PETG, and more. Each material has its properties, making it suitable for different applications.

- Layered Construction: The printer lays down successive layers of melted plastic, allowing for complex geometries and intricate designs.

- Warm-up Process: The process requires the filament to reach its melting point, which varies depending on the type of material used.

- Cooling Mechanism: Each layer must cool and solidify before further layers are added, ensuring structural integrity.

Applications of FDM 3D Printing in Business

FDM 3D printing is not just a trend; it is a revolutionary technology that is reshaping several industries. Here are some of the main areas where FDM 3D printing is making an impact:

1. Product Design

In the realm of product design, FDM 3D printing allows designers and engineers to create prototypes quickly and cost-effectively. With rapid prototyping, businesses can:

- Iterate Fast: Test multiple designs in a short time frame, facilitating better decision-making.

- Reduce Costs: Save significant expenses on materials and tooling by utilizing additive manufacturing for prototypes.

- Enhance Collaboration: Provide physical models to stakeholders, making it easier for teams to visualize the final product.

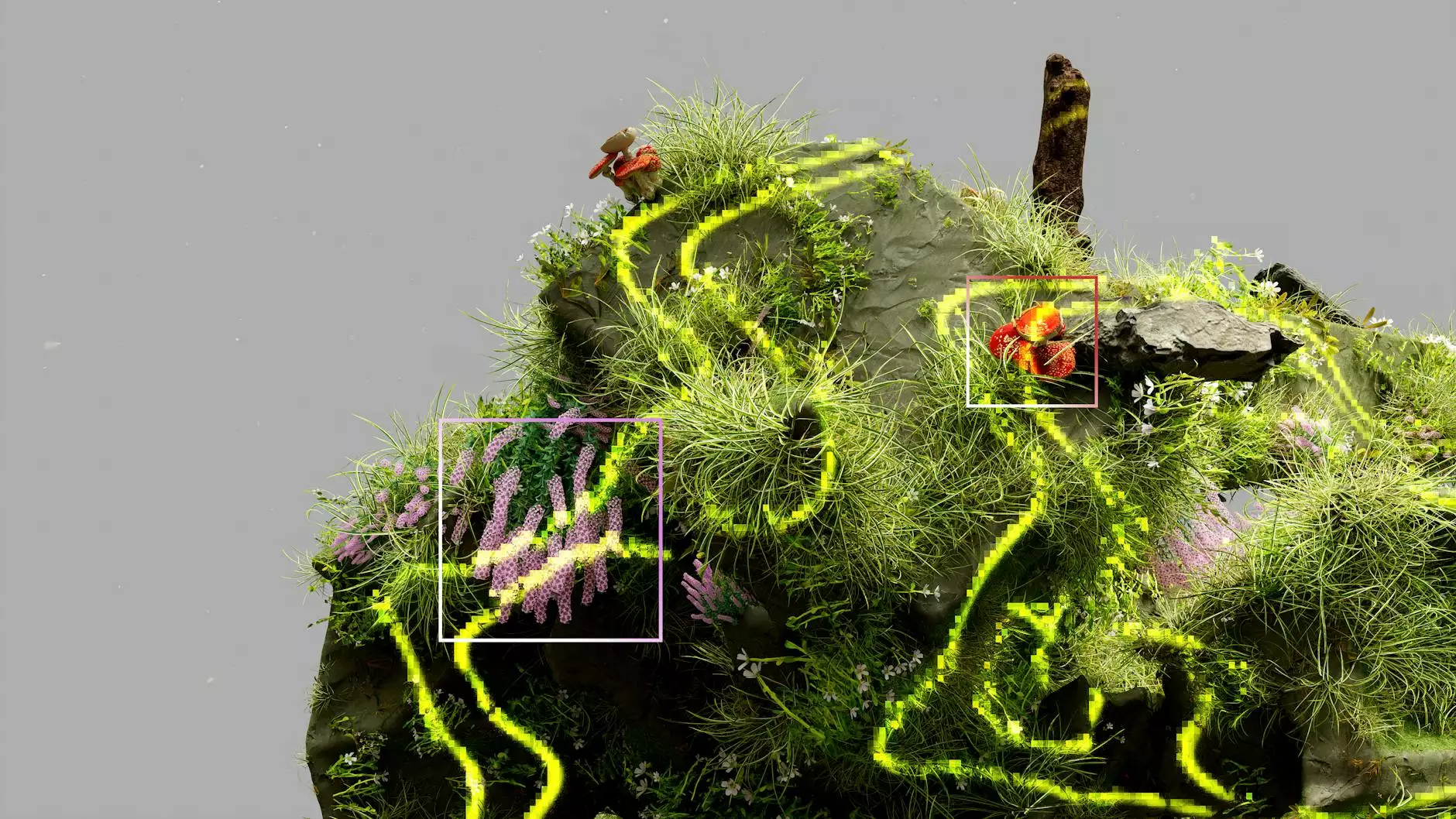

2. Customized Art Supplies

Businesses specializing in art supplies can use FDM 3D printing to produce custom tools tailored to individual artist preferences. This opens avenues such as:

- Customized Brushes: Develop unique paintbrush shapes or sizes that cater to specific artistic techniques.

- Personalized Stencils: Create stencils based on individual designs, allowing artists to express their creativity freely.

- Artistic Sculptures: Print one-of-a-kind sculptures as limited edition pieces that highlight the capabilities of modern 3D technology.

3. Prototyping in Manufacturing

Manufacturers utilize FDM technology for creating prototypes that help in testing functionalities and designs before mass production. Benefits include:

- Speed to Market: Get products from concept to market faster, enhancing competitive advantage.

- Material Efficiency: Minimize waste by only using materials necessary for the prototype.

- Testing Rigor: Conduct rigorous testing of prototypes under real-world conditions to refine the final product.

Benefits of FDM 3D Printing for Businesses

The adoption of FDM 3D printing presents several undeniable benefits to businesses:

Cost Efficiency

One of the most significant advantages of FDM 3D printing is its cost efficiency. By eliminating the need for traditional manufacturing processes—like molds and tooling—companies can:

- Lower Production Costs: Reduce upfront investments and operational expenses.

- Decrease Material Waste: Utilize only the necessary amount of material, promoting sustainability.

Increased Design Flexibility

FDM 3D printing provides unparalleled design flexibility, allowing for:

- Complex Geometry: Create intricate designs and geometries that would be impossible with traditional methods.

- Rapid Changes: Modify designs and produce iterations quickly without significant downtime.

Streamlined Supply Chain

Integrating FDM 3D printing into a supply chain can lead to optimization in several areas:

- On-Demand Production: Produce parts only when needed- reducing inventory costs.

- Localized Manufacturing: Print products closer to their end-users, reducing shipping times and costs.

Challenges and Considerations

While the benefits are compelling, businesses must also consider certain challenges associated with FDM 3D printing:

Material Limitations

Although various materials are available, not all materials are suitable for every use. Companies should:

- Research Material Properties: Understand the mechanical and thermal properties of chosen materials.

- Conduct Tests: Implement rigorous testing on prototypes to ensure durability and performance.

Skill Development

The implementation of FDM 3D technology may require businesses to invest in training staff, which encompasses:

- Understanding Software: Familiarity with 3D modeling and slicing software is crucial.

- Maintenance Training: Regular upkeep of the printers is necessary for consistent output quality.

The Future of FDM 3D Printing in Business

The future potential of FDM 3D printing in business is enormous. As technology advances, we expect:

- Enhanced Materials: Development of new materials that offer better properties, including improved strength and heat resistance.

- Integration with AI: Harmony between AI and 3D printing to automate design processes and optimize production.

- Sustainability Efforts: An increase in the use of recycled materials for 3D printing will push the industry toward eco-friendliness.

Conclusion

In conclusion, FDM 3D printing is transforming the way businesses operate by enhancing product design capabilities, lowering costs, and offering valuable customization options. As technology advances, the ability to harness this innovative method will give businesses a significant edge in an increasingly competitive market. Companies like arti90.com are leading the charge in integrating FDM technology into their operations and embrace the timelines of tomorrow’s innovations. Embracing FDM 3D printing not only promises enhanced efficiency but also the ability to shape a future filled with endless possibilities.